IMAGE 2 Contemporary aerial view marking the location of the old roundhouse between Hiawatha and Minnehaha Avenues, just south of East 26th Street. Photo Credit: Google Earth

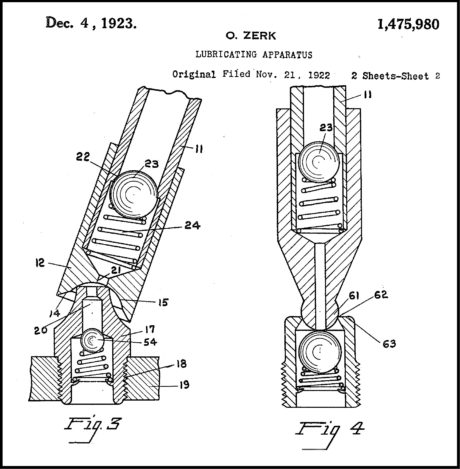

IMAGE 3 Patent diagram showing Oscar Zerk’s ingenious method of injecting grease into internal moving parts.

By JOHN ANDERSEN

A century ago, South Minneapolis was home to thousands of skilled tradespeople.

Right next to our neighborhood was the largest roundhouse of the Chicago, Milwaukee, St Paul, and Pacific Railroad, more commonly known as The Milwaukee Road. The roundhouse had forty-six stalls and was completed before 1900. In the center was a ninety foot electrically operated turntable. Immediately adjacent were the workshops.

Altogether, the maintenance complex was referred to as the Southtown Yards. It was located in the area that today is bounded by Hiawatha, East Lake, 26th Avenue South, and East 26th Street.

A People’s History of the Seward Neighborhood (2018), includes a description of the yards with the interesting fact that some 1,500 mechanics were employed there. Certainly, there were at least as many laborers employed as well.

From wading through the 1940 US Census, I learned about one laborer who worked there from 1928 until 1958. He had the job title of “grease presser.”

What exactly was a “grease presser”?

The grease presser injected grease into wheel axles and driver bushings. With the advent of Zerk fittings in the 1920s, this was done by attaching a grease gun to the fitting, and pumping grease into the bearing. A Zerk fitting is a metal lubrication point.

Before Zerks, there were grease cups that were threaded into bearings just like the Zerks. The cups were filled with “hard grease” that came in large blocks which were cut down, and from which “grease sticks” were made that could be put into the cups.

The laborer filled the grease cup, and then tightened the cap a turn or so at regular intervals, likely based on train mileage. The regular cap tightening forced the grease into the bearing. You knew you had enough grease inside when after tightening, fresh grease oozed out from the side of the bearing.

My personal interest in grease pressers stems from experience as a light rail vehicle technician in Oregon. There, we used grease guns on our trains primarily for couplers, articulation bearings, and axles. Greasing well is somewhat of an art form, especially when you can’t see exactly where the grease is going, and just how much is actually making it to the bearing. Sometimes flashlights and inspection mirrors can help.

Sometimes they can’t.

What always fascinates me is how, even with jobs that at face value seem simple, far more skill is required than meets the eye. Fittings can be hard to reach, and the grease gun must attach to them in the correct manner for the grease to go into the bearing instead of all over the outside housing. In tight areas around engines and axles, there are ways to do this both skillfully and efficiently. Those ways can’t be easily taught. Each mechanic needs to figure this out on their own.

Again, much more than meets the eye.

The Milwaukee Road grease presser would need to know locomotives intimately, and also where to detect likely points of failure. They would also need to carefully inspect all areas requiring grease, and identify components that were broken, about to break, or otherwise defective.

Greasing the train cars was just a tiny slice of the massive maintenance operation at the Southtown Yards. Beyond the roundhouse, there were at least ten other shops and sheds where craftspeople worked, where they daily met unforeseen challenges and found innovative ways to solve them.

Looking ahead, it’s my intention to learn and write about some of the trades that existed there, and the clever techniques craftspeople used to get the job done.

While those trades are now mostly gone, they’re still worth knowing about because they provide a link to the ingenuity and creativity of those who lived in our neighborhood a few generations ago.

Hope you join me in this journey. Let’s see what gems from the past that we can uncover!

About John: John and his wife Mandy are early retiree nomads. John was a maintenance officer and administrative technician in the Air Force, a small business owner, and a light rail vehicle technician. He and Mandy are currently exploring La Paz, in Baja California for six months.